Floor safety is a basic requirement in an industrial setting. For factories, warehousing, and other industrial facilities, floor safety is essential for maintaining safety, productivity, and meeting the requirements of regulatory agencies. The most important investment in this area is the installation of anti-slip floor grating. Anti Slip Floor Grating is designed specifically for the application of securing personnel in areas where there are frequent spills and slip-and-fall hazards due to the presence of many liquid products, oils, dust, and contamination from constant movement. Anti-slip floor grating is not simply a surface; it is a safety system that protects personnel and assets and enables the continuous flow of work.

Understanding the Slip Hazard in Industrial Settings

The unique conditions of an industrial environment present challenges for traditional smooth flooring, making them dangerously insufficient to protect workers.

Common Contaminants: Every industrial environment has spills. Most frequently, spills of hydraulic fluids, oils, water, grease, and chemical solvents, as well as the presence of fine particulate dust, can render an industrial concrete floor into a skating rink in seconds.

Environmental Issues: Cold storage areas will result in the development of condensation, and loading docks that are open to the elements will develop wet surfaces. All these factors contribute to the creation of slippery surfaces.

Frequent Traffic on Smoother Surfaces: The frequent passing of heavy equipment and foot traffic on smooth flooring surfaces will result in the decrease in the friction between the flooring and the feet of the workers over time.

The Mechanism of Anti-slip Grating: The Science Behind the Traction

- Anti-slip Grating cannot be adequately defined by how rough its surface is; instead, it is an example of intelligent design maximizing foot & vehicle traction in all circumstances.

- Surface Topography: Anti-slip grating walking surfaces contain a variety of patterns. Such patterns may be a raised gritted surface, serrated teeth, concave or convex patterns, etc. Because of the elevation of the raised parts penetrating through to the shoe sole, there is no contact between the shoe sole and the raised portion of the grating, thereby enhancing traction.

- Drainage and Debris Removal: The open area of the flooring allows spill recovery to happen without manual cleaning. Additionally, because the grating does not trap dirty liquids or ice between the floor and the walking surface, the anti-slip properties of the walking surface will be maintained indefinitely.

- Material and Coating Improvements: Anti-slip grating has multiple manufacturers using a wide range of materials and coatings to enhance the traction properties of their grating.

THE Materials Used in Industry

The choice of which material to use will depend upon the specific environmental circumstances of the facility. There are several options available, including:

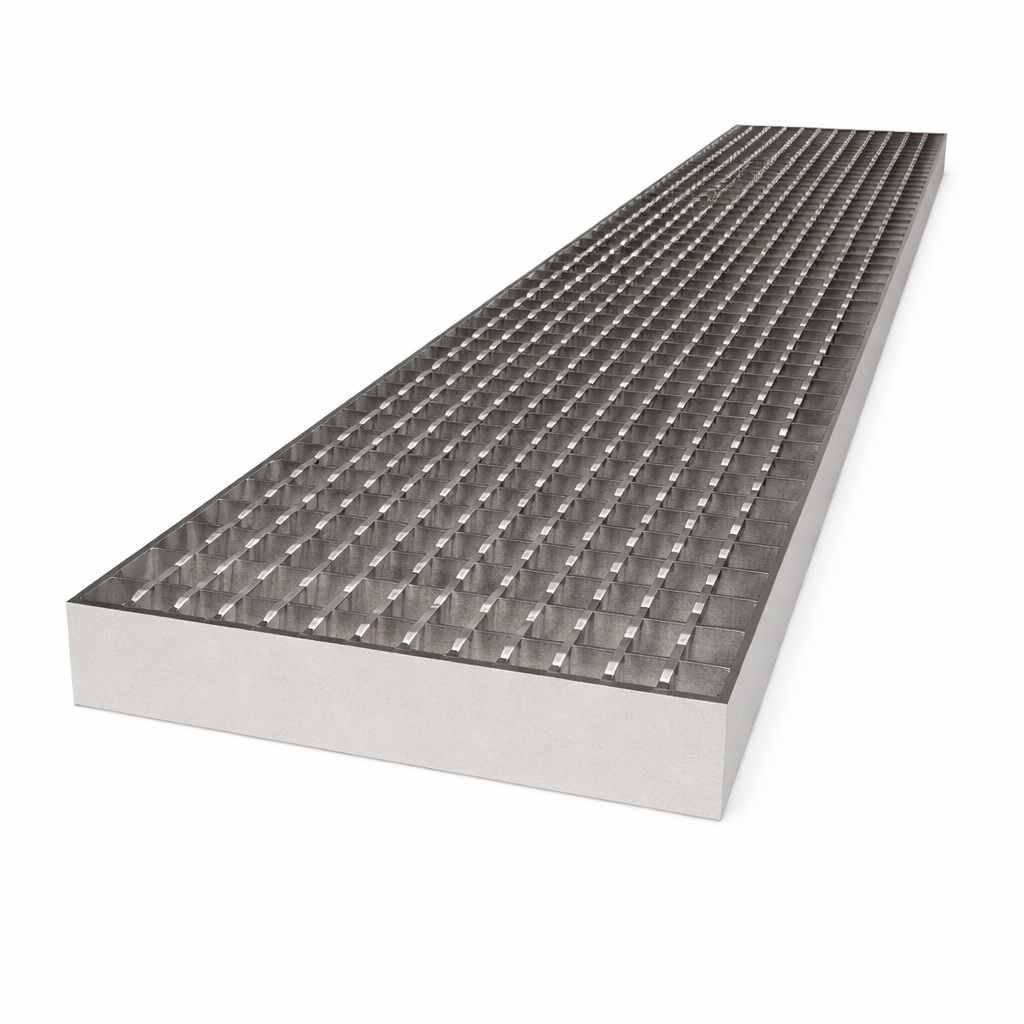

1. Steel Anti-Slip Grating

- Steel Grating: Provides extremely strong and durable performance for supporting the heaviest loads available today. Typically provides an anti-slip surface due to serrated edge tabs that are attached to the supporting bars or a patterned design locked into place using a pressing operation to form the gratings.

- In addition to these specific applications, stainless steel is a requirement for all food processing operations, chemical plants, or environments with high levels of corrosion due to its non-porosity and ability to resist corrosion due to rust.

- Consideration: While steel is typically heavier to install, it may also require painting or galvanizing for the purpose of preventing rust when installed in wet environments.

2. Aluminum Anti-Slip Grating

- Aluminum Grating: Provides an excellent strength-to-weight ratio, naturally resists corrosion, and is a non-spark-generating material.

- Best suited for installations where weight is a concern. In addition, it is typically easier to install and transport when compared to steel.

- Consideration: While aluminum grating is generally less strong than steel in the most severe point load applications, it will work well for most other applications. Read This

3. Fiberglass Reinforced Plastic (FRP) (Grating)

- Characteristics of FRP Grating: FRP is a composite and non-conductive material that is resistant to corrosion and will have an anti-slip feature built into the surface during the manufacturing process.

- Best Uses: Areas that are susceptible to electricity, water treatment plants, chemical processing plants, offshore drilling platforms, and food and beverage processing facilities that are constantly exposed to the corrosive effects of salt, acid, and bleach. Areas that are susceptible to electromagnetic waves and are sensitive to these waves will also benefit from using FRP as a grating material.