Introduction

Syringes are important in the contemporary health care to provide effective and safe medical procedures. Syringes are used in the medical context either in the life-saving vaccinations or in the routine blood collection and insulin administration in hospitals, clinics, diagnostic laboratories, and residential healthcare facilities. As the need to have trustworthy and free of infection medical products is increasing, it is now more than ever that the selection of the most ideal syringe manufacturer in India has gained significance.

India has become a medical device manufacturing centre of world, providing quality, low-cost, and internationally-compliant medical injection syringes. The best syringe manufacturer in India concentrate on precision engineering, high standard sterilization, strict quality and control, and international healthcare standards. This paper will discuss why a manufacturer is the best manufacturer of syringes in India and why Indian suppliers are reliable all over the world.

The relevance of high-quality medical injection syringes

Patient safety is directly related to the use of syringes. This may result in contamination, infection, error of dosage or severe medical complications due to any compromise in quality. Syringes of good quality make sure:

Accurate dosage delivery

Smooth plunger movement

Leak-proof performance

Infection prevention and sterility.

Secure attaching and removing of needles.

Reliable syringes cannot be compromised in the name of vaccination drive, surgical operations, insulin injection, and emergency treatment. That is why, healthcare facilities give preference to the manufacturers which are oriented on safety, adherence and innovativeness.

The Emerging leadership role of India in the production of syringes

In the last ten years, India has developed a fast growth in medical equipment production capacities. It is currently among the largest exporters of disposable syringes exporting to Asia, Africa, Europe, and other continents.

The achievement of the Indian syringe manufacturers is due to:

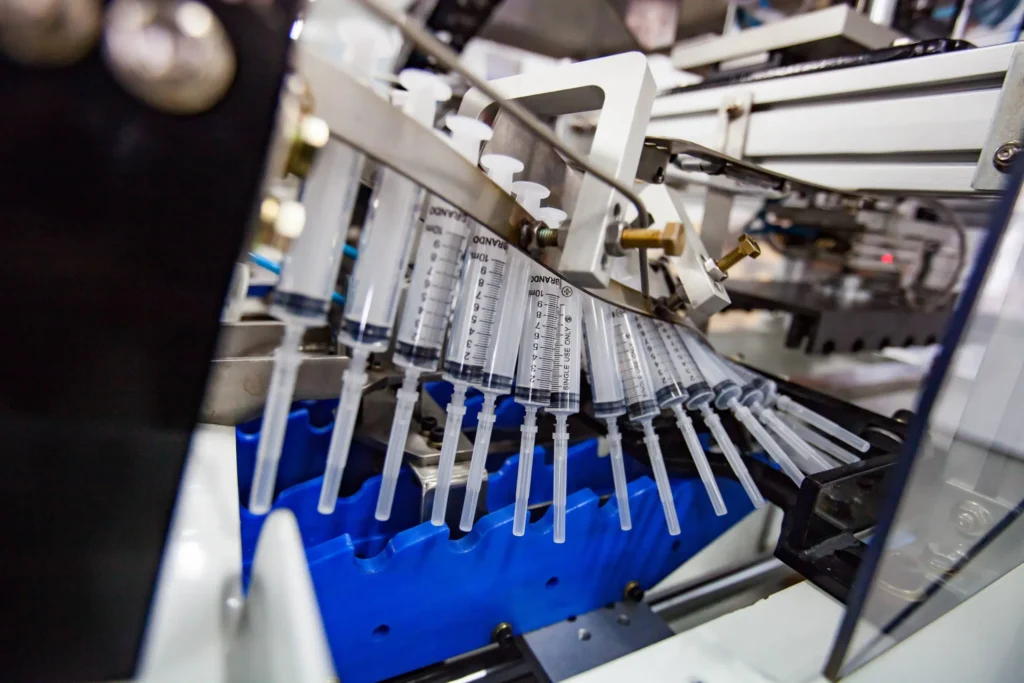

High-tech automated production lines.

Proficient technical labor force.

Tough quality control measures.

Competitive pricing

Conformity to global regulatory requirements.

The finest syringe manufacturer in India is usually under large scale production with the state of the art injection molding machines, assembly lines and sterilization chamber so as to continue with the same quality of products.

Manufactured medical injection syringes types in India

The major syringe producers in India have a large variety of medical syringes to cater to the varied healthcare requirements.

Disposable Syringes

Single-use disposable syringes are hygienic and cross contaminated. They usually come in 1 ml, 2 ml, 3 ml, 5 ml, 10 ml, 20 ml and 50 ml.

Auto-Disable Syringes

Auto-disable syringes have been tailored so that they cannot be reused. They are automatically locked once used and hence are good in immunization programs and government-sponsored vaccinations.

Insulin Syringes

Minimal doses of insulin are administered on insulin syringes. They are produced using very fine needles and transparent calibration.

Luer Slip Syringes and Luer Lock

These syringes have secure means of attaching the needles, these syringes are stable when injecting the patient and so the needles do not just detach accidentally.

Safety Syringes

Safety syringes are fitted with safety measures to avoid needlestick injuries among health professionals.

One of the prime suppliers has a wide range of products to cater to hospital, clinic and export needs.

Quality Standards As followed by the best Syringe makers

Its manufacturer of the best syringe in India has a strict guideline towards quality and internationalization to guarantee international acceptance. Key standards include:

Medical device manufacturing certification in ISO.

European compliance CE marking.

Good Manufacturing Practices (GMP)

The processes of sterilization validation.

Biocompatibility testing

Manufacturers have multi-stage quality inspection involving inspection of raw materials, in-process and final product inspection. Individual batches are tested in terms of sterility and leak testing before being passed to be distributed.

Sophisticated Manufacturing Technology

The current production of syringes is highly automated and minimizes any contact with a person and the possibility of contamination. The Indian manufacturers, who are the leaders, use:

Accurate injection molding machines.

The cleanroom assembly conditions.

Needle bonding systems are automated.

Ethylene oxide (ETO) sterilization.

Batch traceability by using barcodes.

The automation guarantees consistency of barrel thickness, plunger fit and needle alignment. Cleanroom manufacturing rooms avoid gram and microbial contamination, as well as dust.

Sterilization and Safety Measures

Sterility is among the most important production considerations of syringes. The most successful manufacturers employ substantiated sterilization procedures that include:

Sterilization using ethylene oxide.

Sterilization using gamma radiations.

Proper aeration cycles

Sterility-insurance testing.

The syringes are packed separately in a tamper-proof and medical-grade container to ensure sterility before use.

What Indian Syringe Manufacturers have in common with healthcare givers

Global medical distributors, hospitals and government institutions prefer Indian manufacturers due to a number of reasons:

Cost-Effective Solutions

The pricing is competitive, and the quality will not be sacrificed, thus India is the best place to source.

Substantial Production Capacity

Manufacturers who are on top will be able to take bulk orders and their supply will not be interrupted.

Export Expertise

The manufacturers of India possess good export networks and meet the international requirements of documentation and packaging.

Customization Options

The dominant suppliers are offering tailored branding, packaged, and size options according to customer requirements.

Reliable Distribution

Good logistics and supply chain systems guarantee the delivery in time in both domestic and foreign markets.

Sustainability and Environmental friendly practices

Frequently Asked Question (FAQ)

Why is a manufacturer of syringes the best in India?

A manufacturer is the best one due to the rigorous quality control, international certifications, high technology, huge output capacity and stable global supply.

Do the Indian medical injection syringes meet international standards?

Yes, the major manufacturers meet the ISO standards, CE marking or other international regulatory standards.

What are the most common syringes that are produced in India?

There is a wide production of disposable syringes, auto-disable syringes, insulin syringes, safety syringes, and luer lock/luer slip syringes.

Can the Indian syringe manufacturers be used when making bulk export orders?

Yes, the leading manufacturers possess huge-scale production units and export experience to meet the bulk international requirements.

What do manufacturers do in order to be sterile?

They employ validated sterilization methods like use of ethylene oxide or gamma radiations, after which sterility is tested and then they are packaged with close care.

Conclusion

The best syringe manufacturer in India has a distinguishing feature in terms of quality, innovation, safety, and adherence to international standards. Indian syringe manufacturers have acquired world renowned recognition with the well-developed manufacturing plants, strict quality assurance measures and high export capacity.

To improve the safety of patients and the quality of delivered treatment, healthcare institutions all over the world use high-quality medical injection syringes produced in India. With the healthcare sector still emerging, the Indian producers will dominate with new trends, dependability, and superior quality in the creation of medical equipment.