Choosing the right band straps can feel confusing, especially when different options look almost the same from the outside. But behind that simple look, there are many small details that decide how well a band strap will perform. Understanding these details can help you avoid weak products, save time, and prevent sudden breakdowns.

In this guide, we’ll break down the signs of good quality in a simple and friendly way so you can make a confident choice. As you read, you might even discover a few clues that many buyers miss—clues that can completely change your buying decision.

Why Checking Quality Matters Before Buying

Band straps play a steady and important role in various machines and systems. When they are strong and reliable, things run smoothly. When they are not, they can cause delays, extra repairs, and unnecessary costs.

Before buying band straps, it’s worth understanding what makes them dependable. A few minutes of checking can save hours of trouble later. Even if you’re not an expert, you can still look for simple signs that show whether a strap is made well or not.

Look at the Material Strength

The first thing to check is the material. The material decides how long the strap will last and how much stress it can handle.

Note:

If you want dependable Band straps (Correas de banda) for your needs, Pix Trans Spain can guide you with the right information and choices. Contact them to get expert help and make your next selection with full confidence.

Strong materials are usually:

- Consistent in texture

- Smooth, without cracks or breaks

- Flexible but not overly stretchy

- Firm enough to hold shape under pressure

A weak material might look dry, uneven, or cracked. It may also feel too soft or too stiff.

Material Comparison Table

| Feature | Strong Material | Weak Material |

|---|---|---|

| Texture | Smooth and even | Rough or cracked |

| Flexibility | Bends without damage | Breaks or stiffens |

| Surface Look | Clean and uniform | Dull or uneven |

| Durability | Long-lasting | Prone to quick wear |

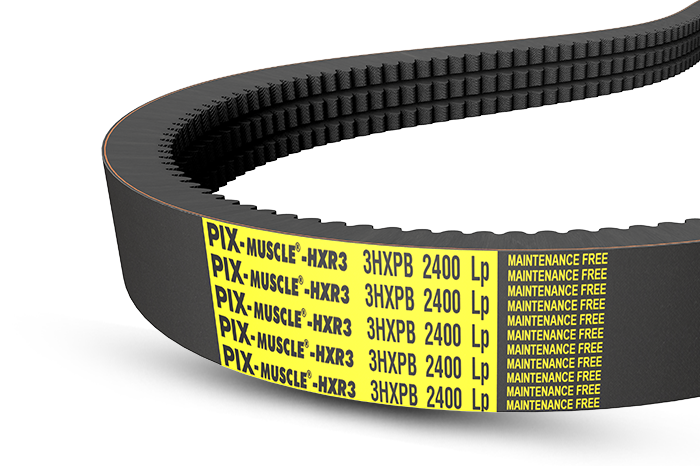

Check the Craftsmanship

Another clue lies in how the strap is made. Good craftsmanship shows that the strap has been created with care, while poor workmanship often leads to early problems.

Things to observe include:

- Even edges with no loose ends

- Consistent thickness throughout

- Neat joins or layers

- No visible damage like dents or cuts

When you gently pull or bend the strap, it should return to its shape without any marks.

Examine the Fit and Finish

Quality bands are designed to fit well in the systems they support. A strap that doesn’t match standard measurements or seems poorly shaped is a sign of low quality.

Good fit also prevents small issues from turning into bigger troubles. Pay attention to the finishing touches—they often reveal how much effort went into making the product.

Fit and Durability Observation Table

| Checkpoint | What You Should See | What You Should Avoid |

|---|---|---|

| Edges | Smooth and aligned | Rough or uneven |

| Thickness | Same across length | Irregular areas |

| Shape | Stable and balanced | Warped or bent |

| Stretch Response | Returns to shape | Remains loose |

Watch for Signs of Consistency

One of the strongest signs of quality is consistency. A well-made band strap will look and feel the same from one end to the other. Any sudden changes in thickness or texture may point to poor manufacturing.

Key consistency clues:

- Even colour

- Smooth surface

- Balanced tension

- Clean appearance

If the strap looks uneven, the difference is not just visual—it can affect performance later.

Ask About Testing and Durability

Some band straps go through tests before they reach the buyer. These tests help ensure they can handle pressure, heat, and long use. While you may not see the tests yourself, you can ask the supplier simple questions such as:

- Has the strap been tested for performance?

- What kind of stress or load can it handle?

- Does it meet any standard guidelines?

Even a short conversation can give you a sense of how reliable the product might be.

Trust Your Observation Skills

You don’t need special tools to spot most quality signs. Trust your senses—touch, sight, and even sound. Sometimes tapping or bending the strap gives clues about its strength. If something feels “off,” it’s worth checking again.

Small observations can help you choose a long-lasting product and avoid unnecessary failures.

Conclusion

Identifying quality band straps is easier than it seems when you know what to look for. Material strength, craftsmanship, consistency, and durability all play important roles. When these factors come together, you get a product that works well, lasts long, and keeps your operations running without worry.

FAQs

1. What is the first sign of a good band strap?

A smooth and even material surface is usually the first sign of good quality.

2. Can I test a band strap without tools?

Yes, simple checks like bending, pulling lightly, and examining the surface can tell a lot.

3. Why do band straps fail early?

They often fail due to weak material, poor craftsmanship, or wrong usage.

4. Should I consider thickness when buying band straps?

Yes, consistent thickness shows good manufacturing and improves performance.

5. Is it important to ask about durability tests?

It helps you understand how well the strap can handle real conditions and long-term use.

For More Infocratic content visit atechvibe