Mining operations depend heavily on safety, structural stability, and long-term ground support. One of the most critical components ensuring these factors is the self drilling rock bolt. Whether it’s for underground mines, tunneling projects, or civil engineering works, choosing the right bolt can significantly enhance productivity, reduce operational risks, and improve overall project efficiency.

But with multiple designs, materials, and performance capabilities available in today’s market, how do you determine which self drilling rock bolt suits your mining environment best? This comprehensive guide breaks down everything you need to know, from bolt characteristics to geological compatibility, to help you make informed decisions that support safe and efficient mining operations. Brands like Argentium have also transformed the industry with advanced rock bolting solutions that meet global standards.

Understanding the Role of a Self Drilling Rock Bolt

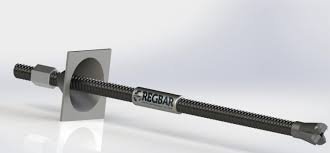

A self drilling rock bolt is a fully threaded rod integrated with a drill bit, allowing drilling, installation, and grouting in a single operation. This gives it a major advantage over traditional rock bolts, which require pre-drilling.

Why are self drilling rock bolts essential in mining?

- They stabilize weak rock formations

- They minimize the risk of rockfalls

- They reduce installation time

- They perform well in fractured or loose geological conditions

- They enhance tunnel support in difficult ground

Because mining environments vary greatly, the correct choice of self drilling rock bolt can influence not only safety but also operational costs.

Key Factors to Consider When Choosing a Self Drilling Rock Bolt

Selecting the right bolt involves a detailed evaluation of geological conditions, load requirements, corrosion resistance, and installation feasibility. Below are the major considerations.

1. Geological Conditions and Rock Type

Your choice of self drilling rock bolt should always begin with evaluating the geological profile of the mine. Factors include:

- Rock hardness

- Presence of fractures or voids

- Moisture levels

- Chemical composition of the rock

For soft and loose strata, bolts with aggressive drill bits ensure proper penetration and high bonding strength. In contrast, harder rock may require carbide bits for durability.

Brands like Argentium provide a variety of bit designs tailored for different rock formations, helping ensure superior anchorage and maximum support.

2. Bolt Material and Strength

Given the high stress and dynamic forces in mining operations, the material quality of the self drilling rock bolt is crucial.

Common materials include:

- Carbon steel – affordable and widely used

- Alloy steel – for heavy-duty loads

- Galvanized steel – for corrosion resistance

- Stainless steel – ideal for highly corrosive environments

If your mine encounters excessive moisture, acidic groundwater, or saline conditions, corrosion-resistant coatings or stainless steel bolts are recommended.

3. Load Requirements

Determine whether your mining project demands:

- Temporary support, or

- Permanent support

For long-term applications, choose a self drilling rock bolt that offers high tensile strength and consistent load distribution. Different bolt diameters and thread profiles impact load-bearing capacity. Thicker, high-tensile rods are typically better suited for deep mining operations.

4. Grout Compatibility

Grouting enhances the anchoring performance of a self drilling rock bolt, so compatibility between the bolt’s design and the grouting material is key.

Two common grouting options:

- Cementitious grout – cost-effective and widely used

- Chemical resin grout – faster curing and stronger bonding, ideal for urgent reinforcement

Some advanced bolts include hollow rods optimized for uniform grout flow. Selecting the right type ensures proper adhesion between the bolt and rock mass.

5. Installation Requirements and Equipment Compatibility

One major advantage of a self drilling rock bolt is its ability to minimize installation complexity. However, not all systems are compatible with every drilling rig or jumbo.

When choosing bolts, consider:

- Thread type

- Coupler availability

- Drill bit design

- Rod length

- Machine compatibility

Brands like Argentium engineer their rock bolts to fit standard mining equipment, reducing downtime and streamlining reinforcement operations.

6. Corrosion Resistance and Longevity

Mining environments often expose metal components to harsh conditions. Corrosion can drastically reduce the effectiveness of the bolt and compromise safety.

To maximize longevity:

- Opt for galvanized or coated bolts

- Choose stainless steel for highly corrosive zones

- Use resin grouts that reduce moisture penetration

A well-selected self drilling rock bolt can significantly extend the support lifespan while reducing maintenance costs.

Types of Self Drilling Rock Bolts Used in Mining

Understanding the available bolt types helps you match them with your project needs.

1. Hollow Bar Bolts

The most common type, featuring a hollow steel tube that allows simultaneous drilling and grouting.

Best for:

- Weak or collapsing ground

- Underground mines

- Tunnels requiring rapid stabilization

2. Friction Bolts

These rely on mechanical friction instead of grouting.

Best for:

- Mines needing quick, temporary reinforcement

- Hard rock environments

3. Expansion Shell Bolts

These anchor into the rock by expanding the shell at the end of the bolt.

Best for:

- Hard, competent rock

- Projects needing long-term stabilization

4. Resin Bolts

Used with chemical resins for a strong and fast-setting anchorage.

Best for:

- Areas requiring immediate load-bearing support

- High-vibration environments

A well-designed self drilling rock bolt system may even integrate advantages from multiple bolt types, depending on the manufacturer.

Benefits of Using the Right Self Drilling Rock Bolt in Mining

Choosing the correct bolt offers several major operational advantages:

Improved Safety

Reduced risk of rock collapses and better ground stability.

Reduced Installation Time

Drilling and grouting in one step speeds up operations.

Cost Efficiency

Longer lifespan and fewer replacements reduce long-term costs.

Better Performance in Weak Ground

Self drilling bolts are designed to stabilize even the most challenging strata.

Versatility Across Mining Applications

From underground excavation to shaft sinking, the right bolt supports multiple project types.

Why Brands Like Argentium Stand Out

Companies such as Argentium have raised industry standards by focusing on the engineering precision, durability, and adaptability of rock bolting systems.

Their solutions offer:

- High-strength steel rods

- Advanced drill bit technology

- Consistent grouting performance

- Compatibility with global mining equipment

- Tested reliability in real-world conditions

By choosing a trusted brand, you ensure that every self drilling rock bolt in your project performs exactly as expected, even in the toughest mining environments.

Conclusion

A self drilling rock bolt is more than just a structural support component, it is a crucial investment in safety, efficiency, and long-term performance in mining operations. By evaluating geological conditions, material strength, grout compatibility, corrosion resistance, and equipment fit, you can select the right bolting system for your project.

With advanced solutions from innovative brands like Argentium, mining teams can achieve reliable ground support, reduce operational risks, and enhance productivity. The right bolt not only strengthens your infrastructure but also ensures that your mining project progresses smoothly, safely, and efficiently.

If you’re committed to building strong, secure, and high-performing mining operations, choosing the ideal self drilling rock bolt is the first step toward long-term success.