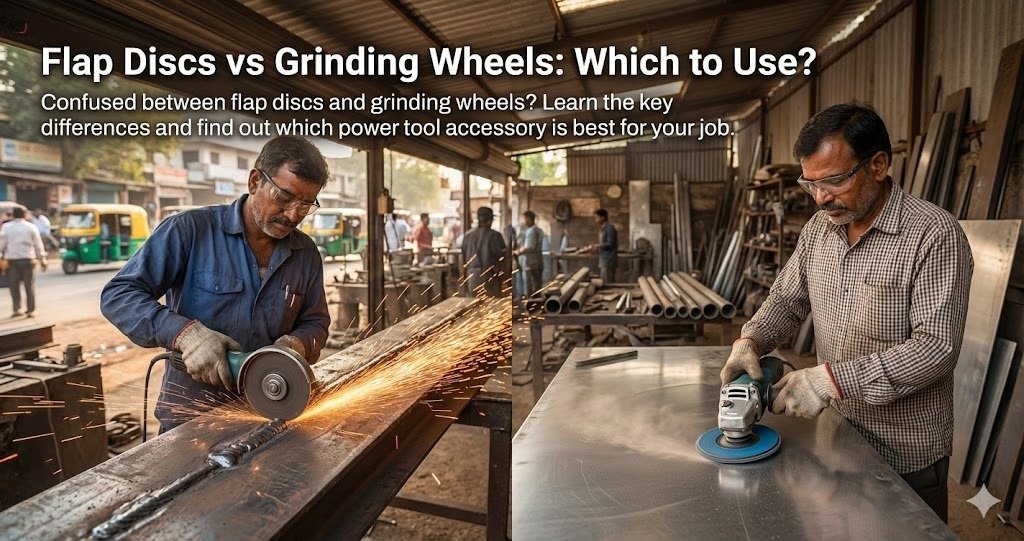

Choosing the right abrasive tool is crucial for achieving professional results in metal fabrication. For years, grinding wheels have been the go-to for aggressive material removal. However, with the rise of versatile alternatives like flap discs, many fabricators are left wondering which tool is best for their specific needs. Understanding the differences between these two power tool accessories is key to maximizing efficiency, ensuring safety, and producing a high-quality finish.

This guide will break down the comparison between flap discs and grinding wheels, helping you make an informed decision for your next project. We’ll explore their distinct characteristics, ideal applications, and critical safety protocols. By the end, you’ll know exactly when to reach for a grinding wheel for heavy-duty work and when a flap disc will give you that perfect, smooth blend.

Key Differences: Construction and Performance

At first glance, flap discs and grinding wheels might seem to serve a similar purpose, but their construction and resulting performance are fundamentally different.

Material and Design

Grinding wheels are solid, bonded abrasive wheels. They are typically made by mixing abrasive grains (like aluminum oxide or silicon carbide) with a bonding agent, which is then molded and fired at high temperatures. This creates a hard, dense wheel designed for aggressive grinding and cutting. The entire wheel is an abrasive surface, which wears down over time, exposing new sharp grains.

Flap discs, on the other hand, are constructed from multiple overlapping pieces, or “flaps,” of abrasive-coated cloth material. These flaps are arranged radially and attached to a rigid backing plate. As the disc is used, the top layer of flaps wears away, revealing fresh, sharp abrasive material underneath. This self-sharpening characteristic provides a consistent cutting rate throughout the life of the disc.

Application and Finish

The primary distinction in their application lies in the finish they produce.

- Grinding Wheels: Excel at rapid, heavy material removal. Their rigid structure makes them ideal for tasks like grinding down welds, removing large burrs, and preparing surfaces for welding where a rough finish is acceptable. However, they can leave deep gouges and a coarse surface that requires additional finishing steps.

- Flap Discs: Offer a unique two-in-one advantage by both grinding and finishing simultaneously. They remove material effectively while producing a much smoother, more refined surface than a grinding wheel. This blending capability often eliminates the need for a secondary finishing tool, saving time and labor.

Operator Comfort and Control

Working with power tools for extended periods requires attention to operator comfort. The noise and vibration produced by grinding wheels are significantly higher than those from flap discs. The flexible nature of the flaps absorbs more vibration, leading to a smoother operation, reduced operator fatigue, and greater control. This makes flap discs a more comfortable choice for detailed blending and finishing work.

When to Use Flap Discs

Flap discs are the superior choice when you need a combination of material removal and a smooth finish. Their versatility makes them a valuable asset in any workshop.

Blending and Finishing

This is where flap discs truly shine. They are perfect for blending welds seamlessly into the surrounding metal, creating a smooth, uniform surface that is ready for painting or coating. The flexible flaps conform to contours and curves, allowing for a polished result without the harsh scratches left by traditional grinding wheels.

Deburring and Edge Chamfering

After cutting or drilling metal, sharp edges and burrs are an unavoidable safety hazard. Flap discs make quick work of deburring, smoothing sharp edges to create a clean, safe-to-handle workpiece. Their controlled aggression is ideal for chamfering edges without removing too much material.

Surface Preparation and Cleaning

For tasks like rust removal, paint stripping, or general surface cleaning, flap discs offer an excellent balance of speed and control. They can quickly clean a surface without damaging the underlying metal, preparing it for subsequent processes like welding or painting. The consistent finish they provide ensures better adhesion and a more professional final product.

When to Use Grinding Wheels

Despite the versatility of flap discs, traditional grinding wheels remain indispensable for tasks that demand raw power and aggressive material removal.

Heavy Material Removal

When you need to remove a lot of material quickly, a grinding wheel is the most efficient tool for the job. Their solid construction allows for aggressive grinding of large welds, castings, and forgings. In situations where the speed of removal is more important than the final finish, grinding wheels are unmatched.

Shaping and Sharpening

The rigid profile of a grinding wheel makes it suitable for shaping metal parts and sharpening tools. Bench grinders equipped with grinding wheels are a common sight in workshops for maintaining the sharp edges of chisels, drill bits, and other cutting tools. Their stable form provides the consistency needed for precise sharpening tasks.

Cutting Applications

When fitted on the appropriate power tools, specialized, thin grinding wheels (often called cut-off wheels) are used for cutting through metal rods, pipes, and sheets. Their hardness and composition are optimized for cutting rather than surface grinding.

Safety First: Essential Considerations

Regardless of which tool you choose, adhering to safety protocols is non-negotiable. Both flap discs and grinding wheels operate at high speeds and pose significant risks if used improperly.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses or a face shield, hearing protection, gloves, and respiratory protection to guard against dust and debris.

- Inspect the Tool: Before mounting, inspect every disc or wheel for cracks, chips, or other damage. A damaged abrasive can shatter during operation, causing serious injury.

- Check the Speed Rating: Ensure the RPM rating on the disc or wheel is equal to or greater than the maximum speed of your angle grinder. Exceeding the rated speed can cause the abrasive to break apart.

- Use the Guard: Never operate an angle grinder without the safety guard properly in place. It is designed to deflect debris and contain fragments if the disc or wheel fails.

- Apply Proper Pressure: Let the tool do the work. Applying excessive pressure can cause overheating, damage the workpiece, and increase the risk of kickback.

Making the Right Choice for Your Project

Choosing between flap discs and grinding wheels isn’t about which one is better overall, but which is the right tool for the specific task at hand. If your priority is aggressive, rapid material removal and the final finish is not a concern, a grinding wheel is your most efficient option. For projects that require blending, finishing, and a smooth surface, a flap disc will save you time and deliver superior results.By understanding their unique strengths and applications, you can optimize your workflow, improve the quality of your work, and ensure a safer workshop environment. Stocking both in your toolkit ensures you’re prepared for any challenge that comes your way. At Yuri Power Tools, we believe that using the right power tools and accessories is the first step toward impeccable craftsmanship.

Publisher: Atechvibe