Before a printed circuit board finds its purpose, it’s nothing more than copper paths and silicon. The PCB is only functional when its assembly accuracy and functional performance align. This alignment does not happen by chance. It’s established through precision assembly and verified on in-circuit test fixtures.

In-circuit test (ICT) and functional test fixtures confirm the build quality. One validates that the PCB is assembled correctly at the component and electrical level, while the other tests whether the PCB works as intended under real-world conditions. Do you need both fixtures? Let’s find out.

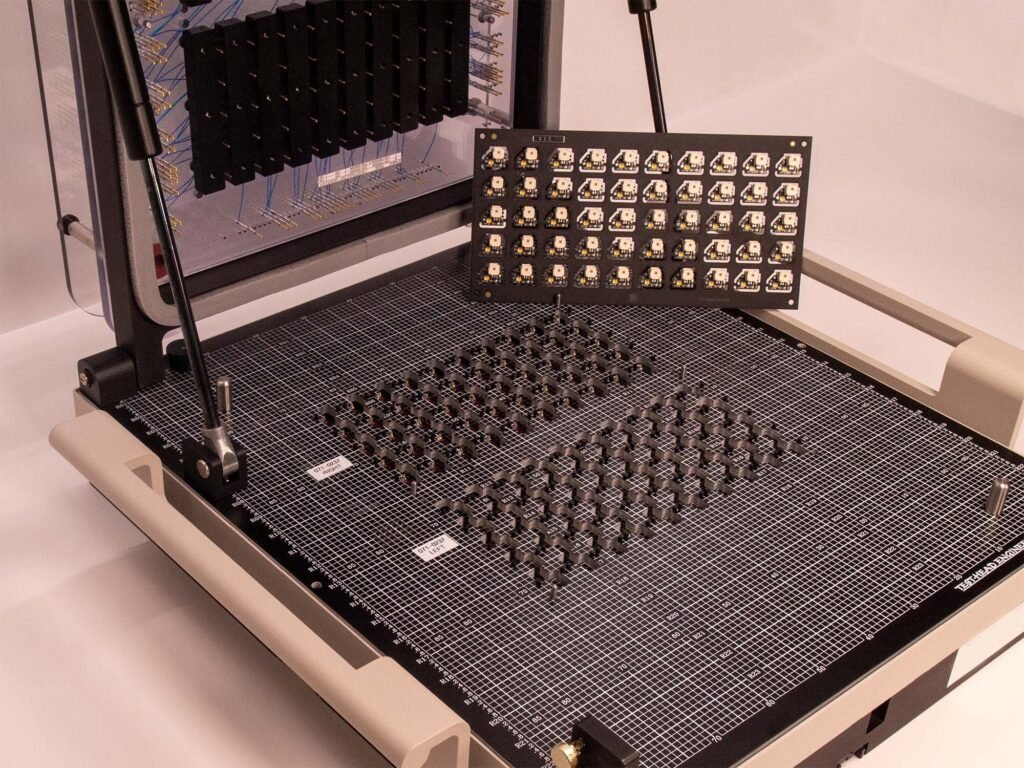

In-circuit test fixtures

An electrical test is done first, before the PCB is allowed to perform. ICT fixtures have pogo pins that test electrical flow. They confirm that every component is in place, that the connection is sound, and the build quality is solid.

What does an ICT fixture do?

- Continuity and opens

- Shorts

- Resistance or impedance checks

- Capacitance or inductance checks

- Diode and semiconductor junction checks

If there is a problem with the PCBA, the in-circuit test fixture will find it. These fixtures can isolate problems to the source. That way, the manufacturer can route the board back for a rework without guesswork.

In-circuit test fixtures are built for high-capacity assembly lines, where speed and repeatability mean efficiency. The fixture itself is custom-built for:

- Accurate alignment

- Consistent contact force

- Mechanical protection

- Fast loading and unloading

- Durability

These features drive the fixture’s non-recurring engineering (NRE) cost and lead time. Manufacturers usually engage a PCBA test fixtures manufacturer for mechanical design, fabrication, wiring, and probe selection for testing accuracy.

What an ICT fixture not verify?

As powerful as these fixtures are, they cannot:

- Verify real-world performance

- Identify intermittent faults that show up only under vibration or temperature

- ICT is a custom-built fixture and can only test what it can access

Functional test fixtures

When in-circuit testing reaches its limits, a functional test takes over to confirm that the PCB matches the intended behavior under real-world conditions. Functional test fixtures focus on whether the PCB performs.

What does a functional test do?

- Verify power rails

- Validate boot behavior

- Check input and output

- Test communications

- Confirm sensors and actuators

- Validate RF performance

- Confirm current consumption and modes

Functional testing powers the PCB for load simulation. By making mechanical alignment and connections, the fixture routes a signal to stimulate and observe behavior. The pass/fail criteria are based on measurement instrumentation for voltage, current, timing, and response.

It doesn’t just verify that there’s a signal transmitting through the board, like ICT fixtures. A functional test verifies that the signal is timed correctly, interpreted correctly, and sustained to undertake the intended load.

This test is automated to ensure every unit is tested the same way, every time. Removing manual interaction, cables, and assumptions in the testing process ensures there’s no variability in the PCB assembly quality.

What can a functional test not verify?

- Pinpoint faults

- Guarantee electrical integrity

- Catch intermittent defects with assembly

- Replace design level verification

- Perform root-cause diagnosis

Unlike an in-circuit test, which validates assembly correctness, functional testing verifies performance. Functional testing does not isolate a faulty assembly to a single net or component; it tests the board as a unified system.

ICT and FT: Do you need both?

In-circuit test fixtures are built to catch manufacturing physics defects, while functional testing exposes system-level defects. Together, these fixtures can isolate root causes and lead to stronger PCB assembly quality.

If the cost of PCB failures is high for your organization, a layered testing process that includes both tests is a worthwhile investment. ICT fixtures, however, become cost-effective in high-density assemblies, whereas functional tests are most effective after exhausting built-in self-tests.

Quality is assembled, then proven

Every PCB carries more than just components. It carries your team’s hard work, your design intent, the precision of assembly, your reputation in the market, and the risk of failure if something goes wrong.

That’s why quality should never be assumed — it should be verified.

A proper testing fixture helps you confirm performance, reduce errors, catch faults early, and ensure every board meets the expected standard before it reaches the customer. Instead of relying on guesswork, you get clear, measurable results.

Try the fixture and let the test results speak for themselves.