Introduction

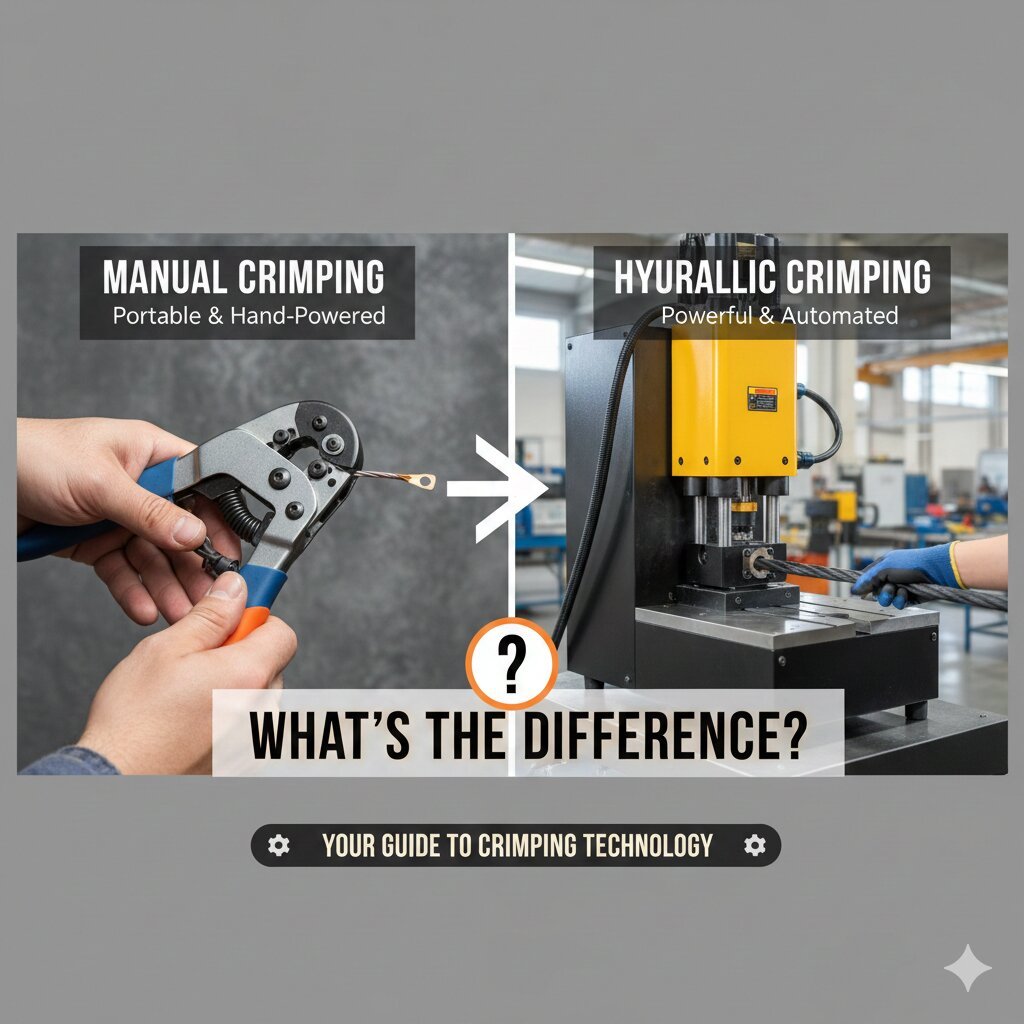

When it comes to electrical and cable assembly work, choosing the right tool can significantly impact your productivity and quality. Two of the most common options in the industry are manual and hydraulic solutions. Understanding how each crimping machine works and where it excels will help you make an informed decision for your business needs.

The choice between a manual crimping machine and a hydraulic crimping machine isn’t just about cost—it’s about matching the tool to your specific applications, budget, and production volume. Both have distinct advantages that make them suitable for different scenarios, from small repair shops to large industrial facilities.

What is a Manual Crimping Machine?

A manual crimping machine relies on hand-operated force to compress and seal electrical connectors onto wires and cables. When you apply pressure to the handle or lever, the machine mechanically forces the crimp jaw to compress the terminal or connector around the conductor.

Manual crimping machines are straightforward in design and operation. They require no electricity or external power source, making them incredibly portable and dependable. Technicians simply place the connector and wire into the die cavity and apply pressure manually. The simplicity of this mechanism means fewer components that can break down, resulting in lower maintenance costs.

These machines are ideal for field work and maintenance tasks where power supplies might be limited or unavailable. Their lightweight construction and ease of use make them popular among electricians, telecommunications technicians, and cable assembly professionals who work on-site.

What is a Hydraulic Crimping Machine?

A hydraulic crimping machine uses fluid pressure to generate the force needed for crimping operations. These machines employ a pump system that pressurises hydraulic fluid, which then drives a piston to compress the crimp die. This approach allows for generating tremendous force with relatively minimal effort from the operator.

Hydraulic systems excel at delivering consistent, repeatable pressure with minimal variation. This consistency translates to higher quality crimps and reduced defect rates. Industrial settings and high-volume production environments benefit greatly from this reliability.

Hydraulic crimping machines typically feature automatic or semi-automatic operation modes, meaning operators don’t need to apply force throughout the entire crimping cycle. The machine handles the heavy lifting, reducing operator fatigue and allowing for faster processing rates.

Key Differences Between Manual and Hydraulic Crimping Machines

Force and Efficiency

Manual crimping machines typically generate 3,000 to 10,000 PSI of force, depending on the design and mechanical advantage of the lever system. They’re suitable for smaller conductors and lighter-duty applications. Hydraulic systems, conversely, can easily generate 10,000 to 50,000+ PSI, making them capable of handling thicker cables and more demanding applications.

The efficiency factor is crucial. With a manual crimping machine, operators must apply consistent pressure throughout the cycle. Hydraulic crimping machines automate this process, reducing physical exertion and speeding up production.

Operating Cost

Manual crimping machines have minimal operating costs. There’s no electricity consumption, no fluid changes, and no complex maintenance requirements. Initial purchase prices are also significantly lower, typically ranging from $500 to $3,000 depending on specifications.

Hydraulic crimping machines involve higher operational expenses. They require regular hydraulic fluid maintenance, pump servicing, and electricity costs. Initial investment typically ranges from $5,000 to $50,000, with premium models costing considerably more.

Production Volume and Speed

Manual crimping machines are best suited for low to moderate production volumes. Skilled operators can complete 20 to 50 crimps per hour, depending on connector type and wire gauge. They’re perfect for maintenance work, repairs, and small-batch jobs.

Hydraulic crimping machines shine in high-volume production environments. Depending on automation features, they can complete 100 to 300+ crimps per hour. For facilities processing thousands of cables daily, this speed difference is transformative.

Portability and Accessibility

The portability of manual crimping machines is unmatched. They require no installation, no electrical hookup, and no special infrastructure. An electrician can carry one in a tool bag and be ready to work anywhere—on rooftops, in crawl spaces, or at remote job sites.

Hydraulic crimping machines require installation on workbenches or mounting systems. They need electrical connections and adequate ventilation for heat dissipation. However, once installed, they provide a dedicated workstation for consistent production.

Precision and Consistency

Manual crimping machines depend heavily on operator skill and consistency. Variations in applied pressure lead to variations in crimp quality. Over a long workday, operator fatigue can degrade consistency further.

Hydraulic crimping machines deliver superior consistency. The machine applies precisely the same force every cycle, resulting in uniform crimp quality. This consistency reduces defect rates and rework, making a big difference in mission-critical applications like aerospace and telecommunications.

Where Each Fits Best: Visualised Scenarios

Choose the Manual Crimping Machine If:

- Field Service Work: Technicians working on-site need portable, self-sufficient tools

- Low-Volume Production: Small batches (under 100 crimps daily) don’t justify equipment costs

- Budget-Conscious Operations: Limited capital for tool investment

- Occasional Use: Cable assembly happens sporadically, not as a primary function

- Remote Locations: No reliable electricity access or power infrastructure

Choose Hydraulic Crimping Machine If:

- High-Volume Production: Processing thousands of connectors daily

- Quality Critical Applications: Aerospace, medical devices, power distribution requiring zero defects

- Cost Per Unit: Long-term savings through faster production and fewer rejects

- Dedicated Workstation: Permanent space allocated for assembly operations

- Operator Comfort: Reducing physical strain during extended shifts

Making Your Choice

The decision ultimately hinges on your specific operational requirements. Calculate your monthly crimp volume, evaluate your workspace setup, and assess your quality standards. For maintenance and field service, a manual crimping machine provides excellent value and independence. For production-oriented facilities, a hydraulic crimping machine delivers efficiency and consistency that pays dividends over time.

Conclusion

Both manual and hydraulic crimping machines serve important roles in modern industry. Understanding their differences—force capacity, speed, cost, and consistency—empowers you to select the right tool for your applications. Whether you need the portability and affordability of a manual machine or the speed and precision of hydraulic systems, the market offers solutions tailored to virtually every operational profile. Assess your needs carefully, and you’ll find the perfect crimping machine to drive your business forward.

Thanks, Atechvibe.com