Installing a new roof is the most challenging stage in new construction and renovations. Roofers approach roofing with particular care. Roofers use a variety of roofing materials and coverings. You can choose easy-to-install soft roofing or durable copper roofing. Despite the differences in building materials, proper roofing technology and no skipped steps are necessary during installation. This will determine the protection of your home from cold and moisture, as well as the longevity of your roof. Roofing technology, which we’ll discuss, is crucial for ensuring longevity.

To fully understand the topic, consider three questions.

1. Types of roofs

The variety of roofing structures is represented by the following types: pitched roofs, gable roofs, hipped roofs, multi-gable roofs, mansard roofs, and hipped roofs. These types differ from each other in appearance. Significant differences are also evident in the time required to erect a roof. A pitched roof is the simplest and quickest to construct, while a hipped roof, for example, will take considerably longer.

2. Basic elements of the roof structure

Almost all of the roofs we’ve listed have a standard set of elements. However, the load parameters on them must be taken into account. We’ll examine the optimal element characteristics for standard roofs.

- The wall plate is the beam that supports the rafters. It distributes the loads across the walls of the structure. The standard cross-section of the material is 150 x 150 millimeters;

- Ridge beam – a purlin placed on the top of the roof to support the upper ends of the rafters. The boards are typically 50 x 200 mm in size;

- The uprights are the element that supports the ridge beam. The beam cross-section in this case can be one of two sizes: 100×10 or 100×150 millimeters;

- Additional elements such as ties, purlins, and braces are also used. They are available in two sizes: 50×100 and 100×150 millimeters;

- To create the lathing, two types of materials are used: a 50×50 slat or a 20×150 mm lathing board;

important note: Looking for reliable Metal Roofing Companies Carbondale KS? Get expert installation, repair & maintenance services with durable materials and free estimates. Call today!

3. Procedure for performing roofing works

Firstly, it is necessary to take measurements of the building frame to avoid any unforeseen situations during the project;

Next, the roofers prepare their tools (they have a large selection) and building materials. Before installing the elements, the lumber is treated with a preservative.

The first step in roof installation is installing the wall plate, and the process is completed with the roofing. If the roof is intended for a warm structure, then thermal insulation (roofing layer) must be installed.

Let’s take a closer look at all the installation stages:

1. Installation of the wall plate

Most often, the wall plate is secured using anchor fasteners, which are attached to a reinforcing frame made of steel rebar. This frame, in turn, is embedded in a reinforced concrete belt. A reinforced concrete belt is a concrete structure installed along the perimeter of flat walls.

2. Fastening the rafters to the wall plate

The installation of the legs is very simple – the profiles are fastened with wooden screws, and the structure is also reinforced with long nails.

3. Installation of rafters

We’ll examine this step using a pitched roof as an example. This type of pitched roof system allows for the entire installation to be completed on the roof itself. The ridge beam is installed as a support beam at the beginning of the process, and the ridge beam itself will be laid on top of it later. All fastenings are made using metal or profile fasteners.

4. Roof thermal insulation

The thermal insulation layer is laid using either basalt wool or expanded polystyrene boards. All joints are insulated with tape.

5. Roof waterproofing.

The waterproofing layer is installed from the eaves to the ridge. This stage protects the structure from leaks during rain or snowmelt. It can be installed in two layers or with a waterproofing membrane. Builders often use hydrophobic materials, so a membrane is not required.

6. Installing the lathing

This is a relatively easy step of all roofing work. When fastening the sheathing, roofers connect the beams to the rafters using screws, nails, and other fasteners.

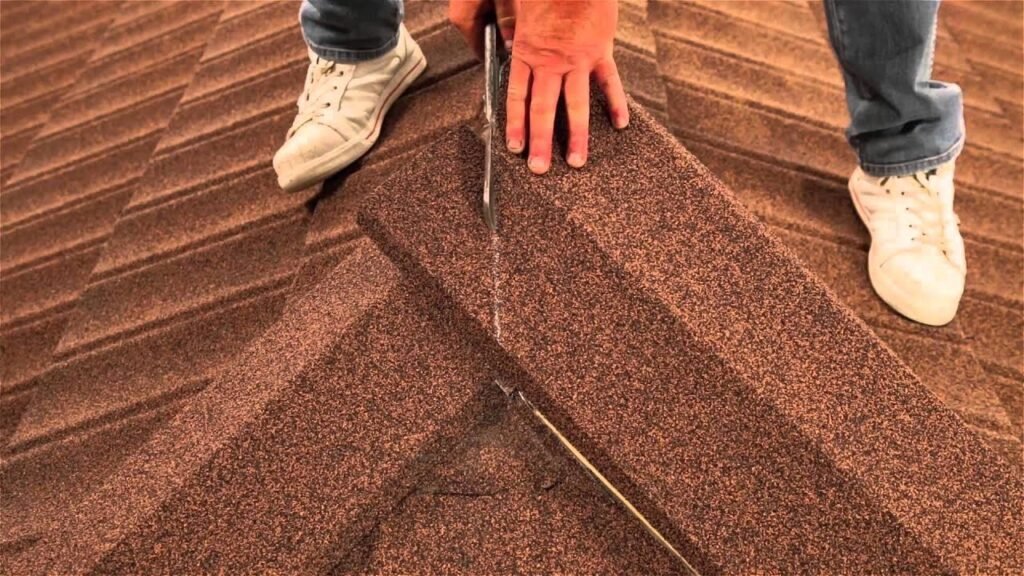

7. Laying the covering

The final stage of roofing work is roofing installation. Depending on the chosen material, installation procedures may vary slightly. It’s worth noting that the material is laid in a staggered pattern when using tile roofing. The quality of this final stage determines the lifespan of the roof and, of course, its aesthetic appearance.

Conclusion

We’ve covered all the stages of roofing work necessary for a high-quality roof. Absolutely all types of roofs require proper procedures to ensure the structure lasts a long time, retaining heat inside and pleasing in appearance. Regardless of the type of roof and covering you choose, the final result will depend on compliance with installation standards and regulations.