Introduction

Some of the most important items in medical practice today are medical injection syringes. Whether in regular check-ups and blood tests or in an emergency procedure, syringes are very important in the safe and effective medical practice. The increased need to have reliable, sterile and precision-engineered syringes has made it imperative that healthcare providers collaborate with a leading manufacturer of medical injection syringes that value quality, safety and innovativeness.

With the future trends in healthcare standards around the world, hospitals, clinics, laboratories and pharmaceutical firms are trying to find Medical injection syringe manufacturer that provide them with steady quality, regulatory conformity and high level of production. The manufacturer can be trusted to make sure that all syringes are of high medical standards without being too expensive or inefficient in the supply chain.

High-Quality Medical Injection Syringes: Importance

Syringes of medical injections have a direct influence on the safety of patients. Substandard syringes may cause mistakes in dosage, contamination, leakages or needle injuries. That is why healthcare institutions cannot afford to make a compromise when it comes to picking a supplier.

A leading production company of medical injection syringes is concentrated on:

- Correct dosage measurement.

- Smooth plunger movement

- Leak-proof barrel design

- Sharp, durable needles

- Adequate sterilization and packaging.

All of these characteristics guarantee the safety of medications, less pain in patients, and decrease the threat of infection.

High-end Manufacturing Infrastructure

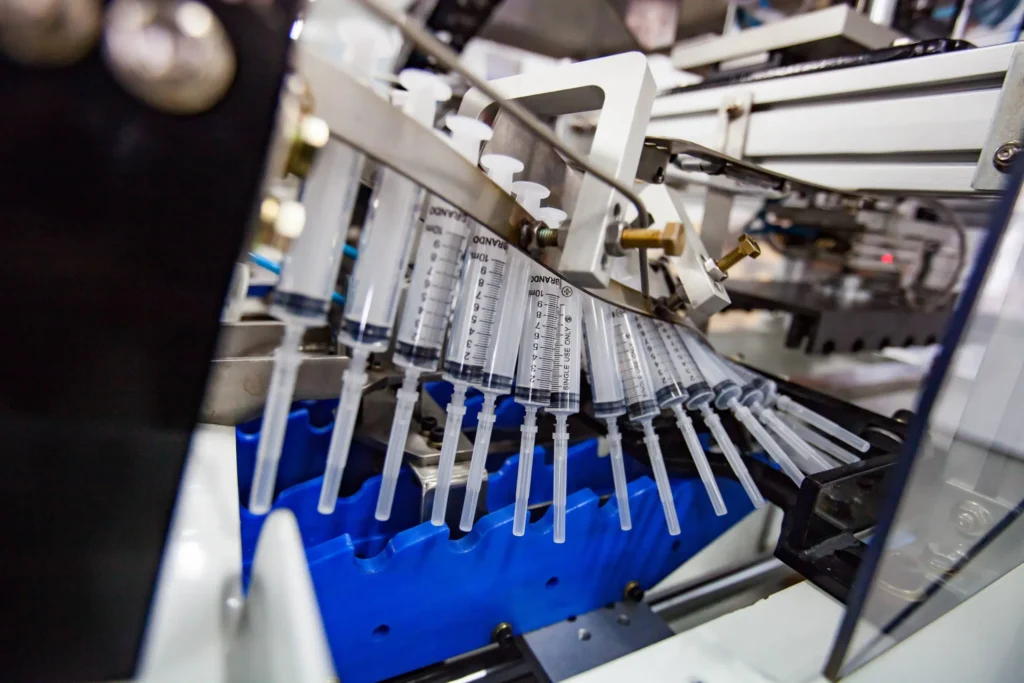

The major producers invest in new production plants with automated equipment and cleanroom conditions. To ensure a contamination-free production, cleanrooms are needed. Air filtration, temperature, and rigid hygiene rules will make sure that syringes are sterile during the production process.

Automation is significant in ensuring consistency. Molding machines are controlled by computers that produce accurate syringe barrels and plungers and assembly lines are automated making human error less. This technological advancement coupled with skills ensures that production is in large volume and quality is not compromised.

Severe Quality Tests and Control

A company that is the best manufacturer of medical injection syringes has the quality as one of its characteristics. All levels of production are highly inspected and tested. Raw materials are selected well and tested to be of medical grades. The finished products are tested based on:

- Sterility

- Durability

- Needle sharpness

- Leakage resistance

- Graduation accuracy

Random sampling and batch testing also makes sure that the international safety standards are adhered to. Another test done by manufacturers is biocompatibility, which is a test that ensures safety of the material to be used by the medical profession.

Adherence to International Standards

Healthcare markets across the globe need a very high level of compliance with regulatory frameworks. The reputable manufacturers of syringes also adhere to the internationally accepted standards including:

- Quality management certifications of ISO.

- CE European market marking.

- FDA compliance of the regulated regions.

Regulatory compliance is used to assure that syringes are safe and have hygiene and performance standards needed to be used in medicine globally. This compliance generates confidence among the distributors and healthcare institutions.

Medical Injection Syringes Types

One of the major producers provides the broadest variety of syrenge types to satisfy the various medical requirements. These typically include:

Disposable Syringes

Disposable syringes are designed to minimize chances of cross-contamination, as well as improve patient safety. They are highly utilized in hospitals and clinics.

Insulin Syringes

Protective devices fitted on safety syringes are used to avoid needle-stick injuries among health professionals.

Having a variety of product lines means that a leading manufacturer can guarantee the general medicine solutions, specialized treatment and the solutions concerning the general population health programs.

Sterilization and Packaging Excellence

The syringe manufacture demands sterilization as the prerequisite it cannot be negotiated. Manufacturers of high quality employ a sophisticated sterilization system like the Ethylene Oxide (ETO) sterilization or gamma radiation to kill the microorganisms.

The syringes have been packed separately in tamper proof sterile containers in order to preserve their safety until time of use. Traceability and accountability are ensured through clear labeling using batch numbers and expiration date.

Customization

Customization may include:

- Specific barrel sizes

- Custom needle gauges

- Branded packaging

- Dedicated safety characteristics.

This flexibility also enables the partners to address the local market needs.

The reason why healthcare providers would select a leading manufacturer

The reasons why healthcare providers want to collaborate with a leading manufacturer of the medical injection syringe are the following ones:

- Consistent product quality

- Compliance to strict regulations.

- High-level sterilization requirements.

- Competitive pricing

- Reliable bulk supply

- Strong technical support

These will lead to the long-term relationships and enhanced patient care results.

The Role in Public Health Programs

Syringes used in medical injections are also required during vaccination and disease prevention programs. The governments and international healthcare organizations rely on the reliable manufacturers when it comes to large scale immunization.

Auto-disable and safety syringes will greatly eliminate the chances of reuse and infection spreading. Manufacturers can directly aid the promotion of healthcare in the world by providing high-quality syringes to the population as a part of the public health program.

Future Trend in Syringes Manufacturing

The future of syringes manufacturing is concerned with safety, efficiency, and sustainability. Emerging trends include:

- Intelligent syringes with inbuilt safety features.

- Reduced plastic usage

- Better needle technology in order to have painless injections.

- The production systems are traced digitally to enhance traceability.

Manufacturers that respond to these trends will always be in business and stay relevant in a fast changing healthcare environment.

Conclusion

The selection of a leading Medical injection syringe manufacturer is very important when it comes to patient safety, regulation, and effectiveness of operations in health facilities. Advanced cleanroom production and strict quality control, innovative designs and green practices are only a few of the items that define the pinnacle of excellence within the leading manufacturers.

Even though high-quality syringes are not only medical devices but also lifesaving devices, their quality has a direct impact on the outcomes of healthcare. A reliable manufacturer of choice through the emphasis on sterility, precision, and reliability will become an important ally in the current healthcare provision.

With the ever increasing demand of safe medical devices in the world, the healthcare providers need to collaborate with the manufacturers that show a level of commitment in quality, innovation and safety of patients. By so doing, they empower healthcare systems and help towards the improvement of medical care across the globe.

FAQ

Why would a manufacturer of medical injections syringe be so trustworthy?

A trusted manufacturer adheres to the strict quality controls, superior to the international standards, high-level sterilization approaches, and stability in the performance of a product.

What is the significance of the sterilization of syringes?

Sterilization kills any microorganisms that may cause infection and makes the medical procedure safe to the patient.

What are the common syringes used in hospitals?

Disposable syringes, safety syringes, insulin syringes and auto-disable syringes are frequently used in hospitals with a variety of medical purposes.

What is the safety of syringes used by the healthcare workers?

Safety syringes incorporate safety measures that limit the chances of getting a needle-stick injury, thereby improving the safety of workplaces.

Are the manufacturers of syringes able to offer tailor-made solutions?

Yes, major producers can provide custom sizes of syringes, needle dimensions and even customizing labeling to a dedicated need in healthcare or distribution.