Have you ever wondered why some ankle-foot orthoses hold up year after year while others loosen, crack, or fail far too soon?

Daily use puts constant stress on joints, especially for active users who walk, turn, and load their devices all day. Material choice plays a bigger role than many people realize.

We explain why durability often comes down to smart engineering decisions, especially when a stainless steel AFO joint enters the picture. You’ll learn how material strength affects stability, maintenance, and long-term confidence in everyday movement.

Why joint material defines long-term performance

Joint material influences how an orthosis behaves after months or years of use. Every step creates friction, load, and micro-movement. Over time, weaker materials deform, loosen, or wear unevenly.

When that happens, alignment changes, and the knee or hip compensates. That compensation often leads to fatigue, instability, or discomfort. Stronger materials resist those changes and keep motion predictable.

Durability matters most in real life, not in controlled settings. Patients walk on uneven ground, climb stairs, and pivot quickly. Joints must handle repeated cycles without losing precision.

That’s why modern orthotic design focuses on materials that resist corrosion, deformation, and thread damage. When joints maintain their original shape, the entire lower-limb system works more efficiently. Stability improves, and confidence follows.

Why strength and precision matter together

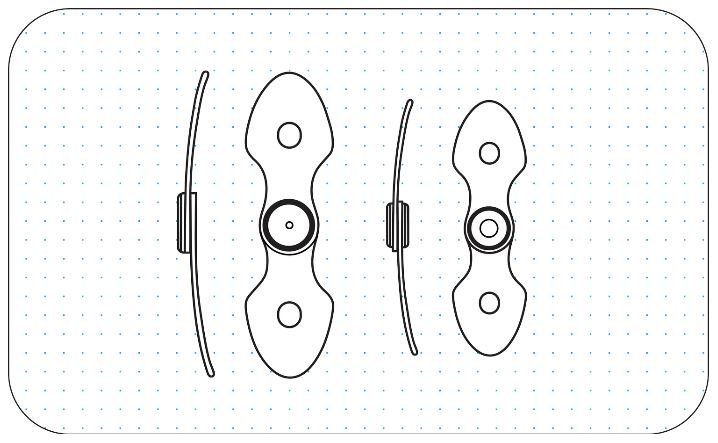

A stainless steel AFO joint performs well because it combines strength with precision. Stainless steel resists bending under load. It also handles repeated flexion without cracking or stretching.

That matters during stance and push-off, when forces peak. Unlike softer alloys or plastics, steel maintains consistent tolerances. Screws stay tight. Bushings stay aligned. Motion remains smooth.

Another key advantage comes from resistance to wear. Daily movement creates friction at hinge points. Over time, that friction enlarges holes or strips threads in weaker materials. Stainless steel resists those failures.

As a result, the joint feels the same after months of use as it did on day one. That consistency supports stable gait patterns and reduces unexpected maintenance visits. For clinicians and users alike, reliability saves time and frustration.

Comparing common joint materials in real-world use

Choosing joint material often means balancing weight, strength, and lifespan.

The table below shows how different materials perform during everyday use.

| Joint Material | Durability Over Time | Typical Issues | Best Use Case |

| Plastic-based hinges | Low to moderate | Cracking, deformation | Low-activity users |

| Aluminum alloys | Moderate | Thread wear, bending | Short-term or lightweight needs |

| Composite materials | Moderate | Delamination under load | Specific custom builds |

| Stainless steel | High | Minimal wear when designed well | Active, long-term users |

This comparison highlights why clinicians often favor steel for demanding cases. The material holds shape, resists wear, and supports predictable motion. That predictability keeps alignment stable and reduces strain on surrounding joints. Over time, fewer adjustments and replacements are needed.

Why does daily movement expose weak joints quickly

Daily life challenges orthotic joints more than occasional testing ever could. Walking involves repeated cycles of loading and unloading. Turning introduces torsion.

Uneven surfaces add unexpected stress. Weak joints show problems early in these conditions. Loosening screws, increased play, or noisy hinges often appear within months.

Stronger designs account for these realities. Precision-machined components reduce unwanted movement. Corrosion-resistant materials prevent degradation from sweat or moisture.

Maintenance, comfort, and long-term confidence

Durable joints reduce more than repair costs. They improve comfort and peace of mind. When a joint loosens, users feel instability immediately. That sensation changes how they walk. They shorten steps or avoid certain movements. Over time, that behavior increases fatigue and limits activity.

A well-built joint minimizes those concerns. Consistent articulation supports natural movement. Reduced maintenance means fewer interruptions in daily routines.

Clinicians also benefit because devices require fewer adjustments. That reliability strengthens trust between provider and patient. A stainless steel AFO joint supports this trust by delivering stable performance through daily wear, not just ideal conditions.

FAQ

1. Why does joint material matter so much in an AFO?

Material determines how the joint handles repeated stress. Stronger materials resist wear and deformation. This keeps motion predictable and alignment stable over time.

2. Are steel joints heavier than other options?

Steel can weigh slightly more, but modern designs minimize bulk. Low-profile construction keeps the difference small. Most users never notice added weight.

3. Do durable joints reduce clinic visits?

Often, yes. Strong materials hold screws and bushings securely. This reduces loosening and wear-related adjustments over time.

4. Can steel joints work for pediatric patients?

Yes. Active children place high demands on joints. Durable materials help devices last longer despite frequent movement.

5. How does corrosion affect joint lifespan?

Moisture and sweat can degrade weaker metals. Stainless steel resists corrosion, which protects threads and hinge surfaces.

6. Are durable joints always the best choice?

They suit most active or long-term users. Clinicians still consider individual needs, weight goals, and activity levels.

The Final Words

Joint durability shapes how an orthosis performs long after fitting day. Strong materials keep alignment stable, motion smooth, and maintenance predictable.

For active users, that reliability supports confidence and comfort during everyday movement. When joints resist wear, the entire device works better and lasts longer.

When you’re ready, reach out to learn which options best support your patients’ or personal mobility goals.